Understanding Dampers in HVAC

In Dampers 101, we explained the basic mechanics of dampers and reviewed the dampers found in HVAC systems. We also discussed the importance of airflow efficiency in Dampers 102. Dampers can do many things in HVAC, but their most common role is directing airflow throughout the system. Control dampers and balancing dampers are the best damper types for this task. In this article, we will cover the traits to look for when designing airflow dampers.

Blade Profiles and Efficiency

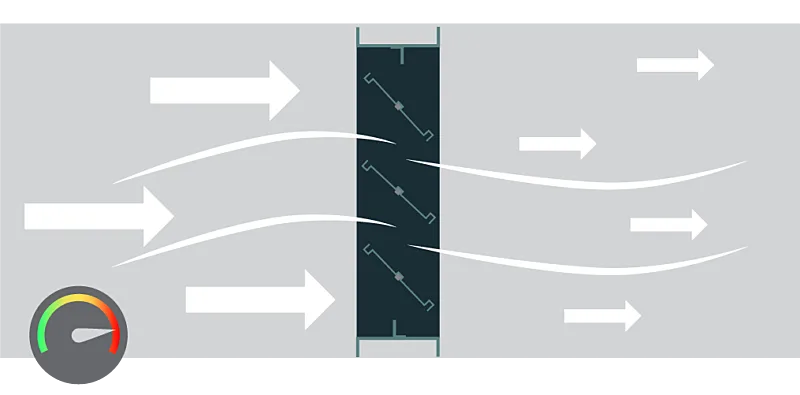

The primary goal of airflow control is efficiency. You want to get air to the right part of your building while expending the least amount of energy. Objects in the air stream will reduce the air pressure of the stream as it flows around the object. This is commonly called “pressure drop” in the industry. It means the air stream will be weaker on one side of the object. The HVAC system can increase fan speeds at key points in the ductwork to regain the lost pressure, but that also means expending more energy to keep the same amount of airflow throughout the system. All dampers will cause pressure drop, but you can minimize their impact on your system.

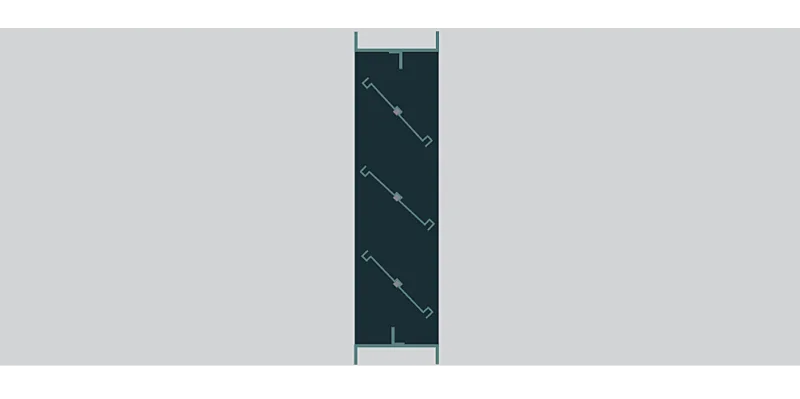

Check the damper’s blade profile. Damper blades are smooth with only a few features. They don’t need to capture rainwater like a louver blade. They need to close tightly. Single-thickness blades are flat along the profile of the blade, except for the curves found on either edge of the blade. These curves interlock when the damper closes, so that the edge of one blade fits into the curve of its neighbors. These curved edges will create resistance as air passes through the damper. Their overall effect on airflow will be negligible, but they create some pressure drop as air passes over the curve.

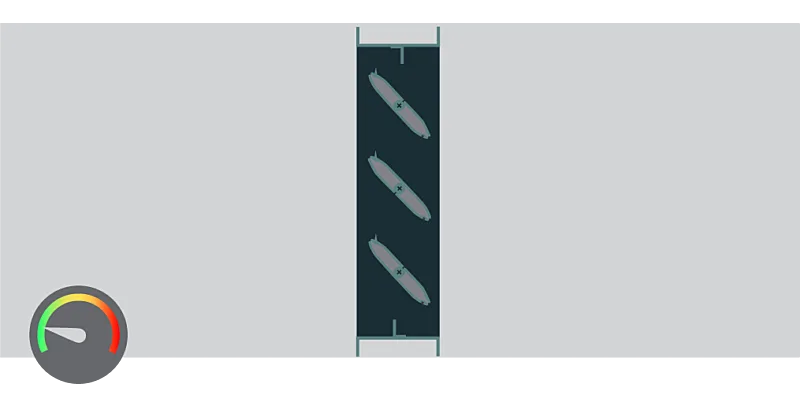

Airfoil blades have a flat, curved profile across the blade. This minimizes resistance against the air stream. Airfoil blades borrow their design from airplane wings, although the curve is more pronounced along the bottom of the airplane wing. The smooth edges of the blade allow air to pass over and under the blade with ease. The airfoil design maximizes airflow efficiency by removing any features that would interfere with the air stream.

The Benefits of On-Face Mounting

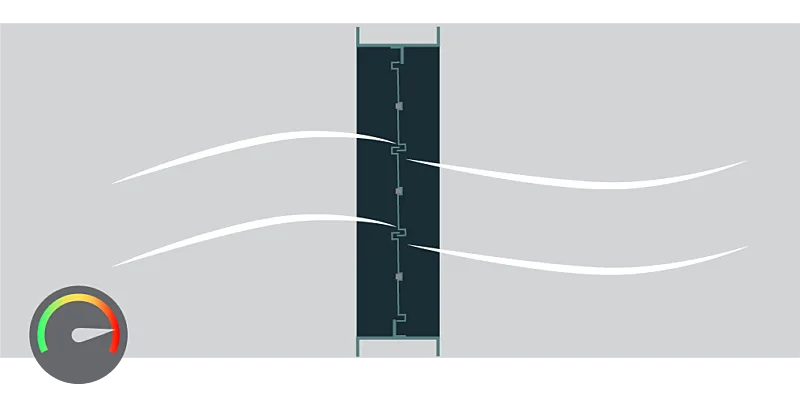

Technicians commonly install control dampers inside the ductwork to fully fasten and secure them in place, known as an in-duct installation. The damper’s frame will be in the airstream and will impact airflow even when the damper is fully open. For on-face installations, the face of the damper mounts onto opening of the ductwork. This option removes the frame from the duct and frees up the airstream. You can free up more space by choosing dampers with in-jamb linkage and mounting the actuator onto the damper’s jamb.

The damper’s blades will be the only object in the airstream with these options in place, providing the most airflow. However, they may not be available for your installation. For example, there may not be enough space in the installation area to accommodate the actuator or the damper’s frame. Or there may not be any means to support the damper from outside of the duct. These options won’t be available in these circumstances. Choose the best options available.

Air Leakage

It's important to minimize pressure drop where possible, but it is also important to consider air leakage. Think about an intersection in your ductwork and you want to pass air down one path. The dampers are closed on the unused sides of the intersection, so that the air stream has a clear path to its destination. A small amount of air can still pass through the closed dampers, especially if it doesn't have seals. This is air leakage. The system will need to expend more power to make up for this leakage. It is also important to minimize air leakage where you can.

You can add blade and jamb seals to control dampers. Seals prevent air from leaking through the damper while it’s closed. On single-thickness blades, the blade seals will sit inside the curves so that they close the gap between the blades. Airfoil blades have seals near the edges of the blade, located in grooves along the blade. These seals overlap with the neighboring blades when the damper closes, providing a tight closure and minimizing air leakage. Air leakage is another crucial factor to consider for airflow efficiency, as it can negatively affect your system’s overall performance. We will stay focused on the pressure drop for now.

Like all things in HVAC, the key to making good choices involves understanding the needs and limitations of the project. Look for areas where you can maximize airflow. Determine the areas in your system that will benefit from tight-closing single-thickness blades. Understand your HVAC system and then design dampers that maximize airflow. Unobstructed airflow contributes to an efficient HVAC system.

AWV and Control Dampers

AWV offers control dampers for meeting HVAC requirements. From commercial to industrial, we build our dampers to your specifications. Each damper fits the installation area and maximizes system performance. Interested in airflow dampers? Contact AWV today. We can help you meet your airflow needs.