Designing Dampers

Dampers regulate airflow and balance pressure through ductwork to keep occupants comfortable. Every damper type plays a role in the system. In Dampers 101, we looked at several types of airflow dampers and discussed their roles in your system. Volume control dampers keep air moving through your system, while isolation dampers prevent leakage between sections of ductwork.

Other dampers serve a similar role but are designed for different environments. A tunnel damper can function like a volume control damper, but its design makes it better suited for heavy duty applications like ventilating transit tunnels. Understanding damper design is important.

In Dampers 102, we will focus on one common damper type found throughout your HVAC system. Volume control dampers regulate airflow through various rooms and zones in your building. Control dampers will open and close to create paths in the ductwork. By opening and closing, these dampers give the system more control over larger areas by concentrating the efforts of the system and help conserve energy.

An efficient control damper does two things:

- It passes air with minimal impact on the flow, and

- It minimizes leakage into other dormant zones.

These two aspects are important criteria for choosing control dampers.

Air Performance

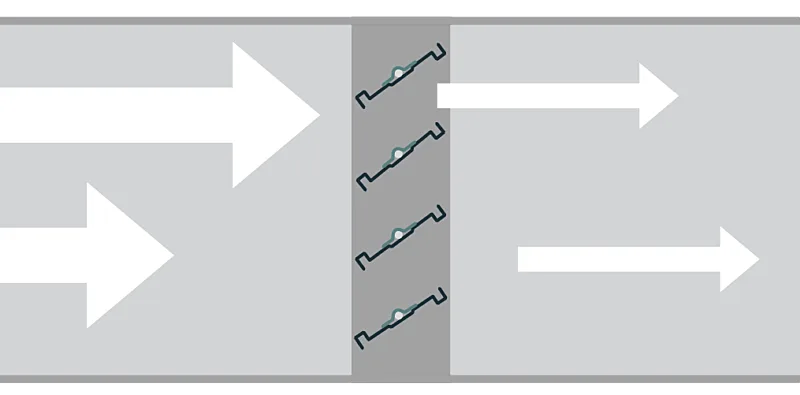

Every damper will impact airflow. Air must pass through the free space between the damper’s blades when it’s fully open. This results in a small amount of pressure loss as air moves from one side of the damper to the other. The amount of loss increases as you add more dampers along the duct leading to the destination.

All equipment in the system will cause pressure drop. If the air loses too much pressure, then the flow at the destination will be weak. System fans can spin faster to make up for the loss, but this expends more energy. It can also put unnecessary strain on the fans.

The key is to minimize pressure drop where possible, so that air can move freely from point to point in the system while expending the least amount of power. Start by looking at the blade profile. Damper blades will typically have a flat design with few blade features. A simple profile is better for airflow.

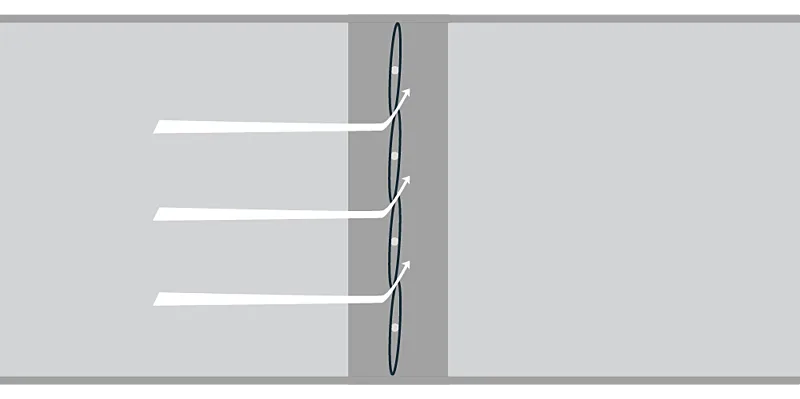

Airfoil blades are the best for airflow. The airfoil has curved edges and a flat body that resembles the wing of an airplane. This design gives them an aerodynamic profile. Air can quickly pass over and under the airfoil blade, with minimal loss in air pressure. Airfoil blades are also hollow to allow for a small amount of warping as air flows through. This allows dampers with airfoil blades to handle airflow at greater speeds.

Single thickness blades will also have few blade features, which minimizes their impact on airflow. However, they will be more rigid than an airfoil blade. They also won’t have the same aerodynamic design. Both blades can work in your damper, but single thickness blades are better suited for addressing another issue with airflow.

Air Leakage

Control dampers will close when air needs to flow to a different zone. By closing, the damper directs air towards the area where it’s needed. For example, someone may turn on the air conditioner in a meeting room to prepare for an upcoming meeting. The rest of the office is at the target temperature, but the meeting room needs to be cooler. Control dampers can close off ducts leading to the office, so that airflow is concentrated on the meeting room. These dampers need to close tightly to minimize air leakage.

Only bubble dampers and isolation dampers are considered airtight, because they are designed to prevent the spread of contaminants and noxious fumes between areas. Control dampers will have some air leakage, even when fully closed. As air moves to the closed damper, it can pass through the small spaces between the damper’s blades and the spaces between the blades and its frame. The amount of leakage may seem minor, but it can quickly add up as air flows from point to point in your ductwork. Minimize air leakage to maintain efficient airflow.

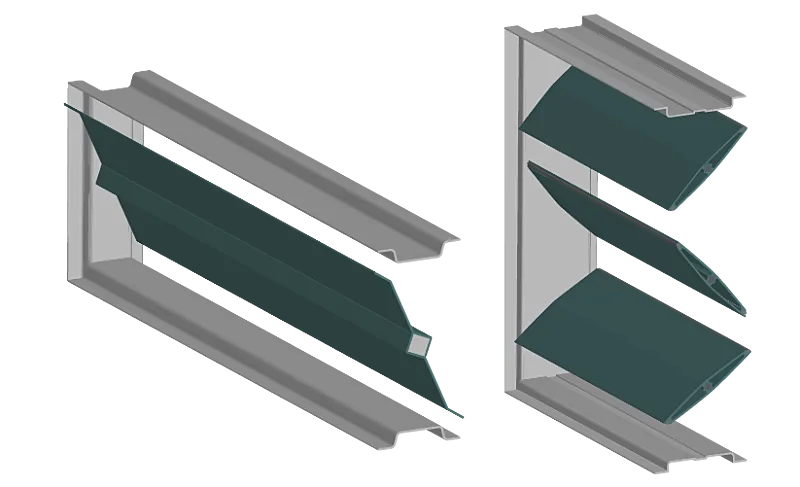

Blade and jamb seals help the most. These features fill in the gaps when the damper is closed, so that there are fewer spaces for incoming air to pass through the damper. Blade seals are placed near the edge of the damper blade. These seals will overlap when the damper closes, so that there is little remaining space between the blades. If your goal is minimizing leakage, check for blade and jamb seals on the damper's submittal.

Airfoil blades can also be equipped with blade seals to help with air leakage. With this, you can receive the benefits of low pressure drop and minimal air leakage. For example, the VC-26 and VC-27 are low leakage control dampers with airfoil blades. These dampers have vinyl blade seals and metallic compression seals at the jambs. These seals minimize the free space of the damper when it is fully closed.

Design for the Application

Each HVAC system is unique, and each part of the system will have unique needs. The airflow requirements will change from point to point. No damper will fulfill every role. Understand the needs of your system. Is there a point in the duct that leads to separate rooms? In this situation, you want to direct airflow to each room.

This situation calls for dampers with seals to minimize air leakage into the other connected rooms. Adding a damper near an intake point? Consider using airfoil blades in this situation to maintain the airflow to the rest of the system. You can improve your system’s overall efficiency by managing pressure drop and air leakage.

AWV and Efficient Airflow

At AWV, we build dampers to meet your project’s needs. We offer dampers with single thickness or airfoil blades to help you manage your HVAC system’s efficiency. Browse our wide selection of volume control dampers online.

Ready to start? Contact AWV today and let’s meet your project requirements together.