Dampers play a crucial role in your HVAC system, whether they are controlling flow or balancing pressure. Choosing the right dampers is difficult, especially when you consider the different types and models available. Your system will need several types of dampers to operate efficiently.

How do you decide which dampers you need? Which dampers will work for your system? Here are a few questions to ask to help you design the right dampers for your project.

Start with the damper type. This will help steer you in the right direction.

What kind of project are you working on?

Is it an office building or a retail space? Standard control and balancing dampers should work for these projects. Are you working on an industrial project like a factory or a plant? You will need control dampers built for heavy duty airflow. Will the finished project have clean rooms that need to be isolated from the rest of the building? Laboratories and computer manufacturers will need these rooms for sensitive work.

HVAC projects will often require more than one damper type to move air to each part of the building. For example, there will be areas in an office building that require pressure balancing to maintain adequate airflow.

Or there may be areas in the building that use spiral ducts instead of square. Divide your project into sections and requirements. Where do you need round dampers installed? Where do you think you will need a balancing damper? Select the damper types that best fit those requirements.

For air control, this is just the beginning of the selection process. Control dampers have a wide range of options available between different models. Here are some more questions to ask yourself when designing a control damper.

Parallel or Opposed?

We cover the difference between these two types in “Parallel and Opposed”, if you would like to know more.

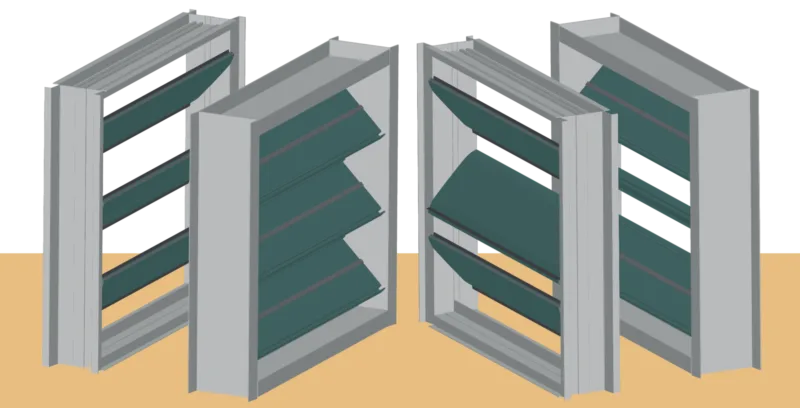

To summarize, control dampers can have parallel or opposed blade action. Each blade action determines how the damper will close and open. Parallel blades are common for most air control applications, but there are benefits to using dampers with opposed blades.

Parallel blades are best for controlling air in quick bursts, with minimal impact on the air stream during closure. Opposed blades will cause more pressure drop when moving to the closed position. This blade action is better suited for modulating airflow and air pressure, while also providing more closing torque when closed. Opposed-blade dampers can double as pressure balancing dampers, when paired with a modulating actuator.

The choice will come down to what you need the damper to do. You are already pointed in the right direction by understanding where the damper goes and what it will do.

Airfoil or Single Thickness?

Control dampers will have either single thickness blades or airfoil blades. This refers to the shape of the blade. Both blades are designed for unimpeded airflow while the damper is open, but there are key differences to consider.

Airfoil blades have a unique, aerodynamic shape that provides excellent flow when open. Their design is much like the wing of an airplane, minus the curve along the bottom used to generate lift. Air passes effortlessly over along the edge of the blade. Airfoil blades provide the best airflow of any other blade type.

Single thickness blades have a mostly flat profile, which is also an excellent design for airflow. However, these blades will typically have hooks along each edge which interlock when the damper closes. These hooks can create pressure drop as air passes along the curve. The loss is minor, but present.

The interlocking blades provide a tight closure, especially with blade seals in place. An opposed-blade damper with single-thickness blades will minimize air leakage in your system while the damper is closed.

If you want to minimize air leakage in your system, then consider adding single-thickness blade dampers. Otherwise, if you’re looking to maximize airflow and system efficiency, then look for dampers with airfoil blades.

Insulated?

Does your damper need to be insulated? Certain dampers will have insulated airfoil blades and the options for a thermally broken frame. These features prevent heat transfer between hot and cold zones. Heat can bleed through a closed damper if it isn’t properly insulated.

This is important in buildings that require precise temperature control or buildings in harsh climates. Areas like walk-in refrigerators, cold storage, or buildings in cold climates. Insulated dampers help cut down on the energy costs needed to heat or cool these areas.

They can also help the system in general, by dividing hot and cold zones in your HVAC system. Heat transfer can lead to wasted power. The system will kick in to cool or heat these zones when it doesn’t need to.

It’s up to you where and when you install insulated dampers.

Actuator?

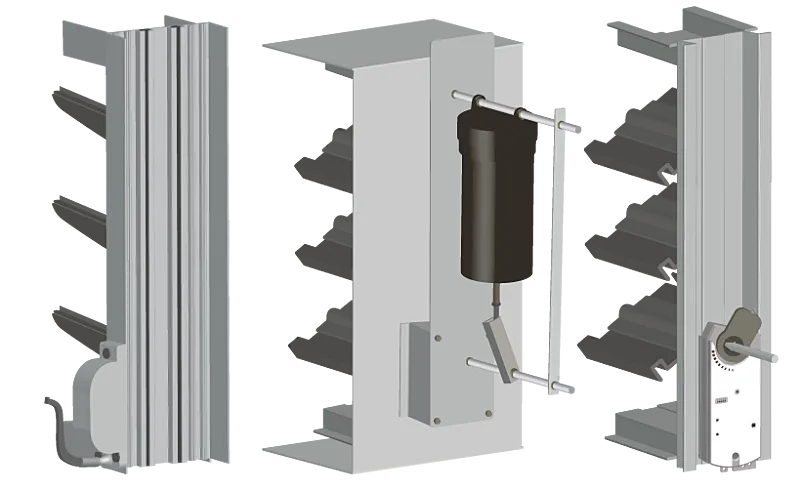

Although it may seem difficult, this question is one of the easiest to answer. What kind of actuator do you need for your damper?

The answer is often an electric actuator. These actuators use electric power to open and close the damper. Modulating actuators can hold blade positions between open and close, which allows the damper to manage air pressure in the duct. Electric actuators can also connect to a central computer system, which can monitor the overall system and open each connected damper automatically.

Electric actuators provide the most options for automation at an affordable price. While versatile, they aren’t always the best option.

Older projects may use an air compressor to feed air to pneumatic actuators, which open and close dampers. It may be more cost effective to equip newer dampers with pneumatic actuators in these cases since the equipment is already in place.

If your damper is out in the open, then you may be fine with using a manual actuator. Manual actuators operate by hand, so they need someone to open or close the damper. Manual actuators are the cheapest, but they should only be used for dampers that can be easily accessed and for dampers that aren’t critical to the system.

The actuator type you choose is up to you. Consider where the damper is going and what it will do in your system.

With these questions answered, you can narrow down your search to the right damper. If you are still stuck between damper models, then check the submittal of each damper. Submittals display performance data like pressure drop and air leakage.

This data can help you further narrow down your search. Damper design isn’t hard when you know what you’re looking for.

AWV and Dampers

If you’re having trouble finding the right dampers, then talk to AWV. We have been building and supplying air control dampers for a long time. We can help you find the right dampers to complete your HVAC system. Contact us today and let’s finish your project together.