Fixed aluminum louvers are used in construction projects for many different purposes. Useful for minimizing sound and light, louvers are a critical component to letting air get where it needs to go while keeping rain and other elements out. Where clean air is needed for both people and machinery, louvers will be there too.

What is a Louver?

A louver is a ventilation product that has been designed to allow the passage of air while preventing the passage of unwanted elements like water, dirt, and debris.

The Design of a Louver

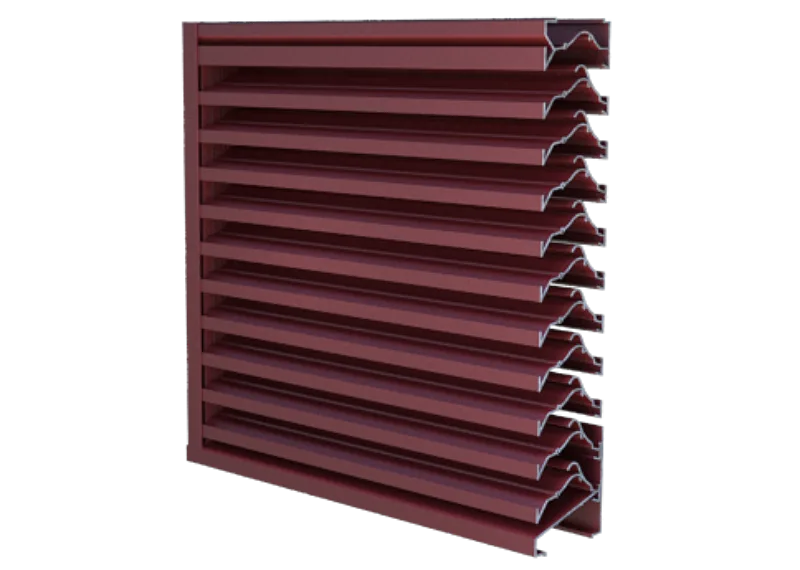

Louvers used for mechanical ventilation are designed to fit in the intake or exhaust openings on a building, or sometimes they are a part of the wall structure. Typically rectangular or round in shape, the frame of the louver mounts securely to the building and consists of blades that fill in the frame. The number of blades used, their depth, and the shape of the slat are all design parameters that affect the cost and performance of the louvers.

Benefits of Fixed Louvers

Louvers can be fixed or adjustable. When using adjustable louvers, the angle of the blades can be changed, either mechanically or with an actuator, often from a fully closed to fully open orientation.

Fixed louvers have blades that remain in a fixed position. Fixed louvers are desirable for many applications where there is no need to adjust and any adjustment might limit the louver’s performance. Fixed louvers help reduce the cost of the louver too.

Placement and Categories of Louvers

Louvers can be used as architectural elements, for ventilation, and for acoustic purposes. Various aesthetic options are available depending on how the louvers will be used and how prominent it will be.

Choosing Fixed Louvers

Choosing the right louvers for an application depends on how they will be used. Knowing the application requirements is key to deciding the correct type, depth, and blade design.

Types of Fixed Louvers

The main types of fixed louvers are drainable and non-drainable louvers.

Drainable Louvers

Louvers with a lip on the edge of the blade are called drainable louvers. The lip serves as a miniature gutter which collects any water that tries to enter the louver. The blade redirects the water to the frame of the louver and drains it away.

Non-drainable Louvers

Blades without these features on the edge are considered non-drainable louvers. Water that tries to enter the louver will simply roll away and fall down the face of the louver.

Choosing Louver Depth

Louvers come in a variety of different depths. The deeper a louver, the farther apart the blades can be spaced and the lower the pressure drop through the louver. Deeper louvers are better at keeping water out with less air resistance, but they can be more expensive. Four to six inch deep louvers tend to optimize cost and performance for many applications.

Choosing Louver Blades

The blades of the louver have a huge impact on how well the louvers will perform. The style of the louver refers to the shape of the extrusion. Many different shapes or profiles are available with various performance and pressure drop parameters.

In addition to the style, how closely packed the blades are will affect how well the louvers can keep out unwanted rain and debris. Most louvers have a free area, the area of the louver available for the passage of air, ranging from 30% to 60%. The farther apart the spacing, the less air resistance, but the easier it is for material to enter the louvers.

AWV Acoustic Louvers

AWV offers 14 fixed non-drainable and 14 fixed drainable, architectural louvers in various frame depths (2 to 6-inches), blade angles, and spacing. Our LF line of fabricated louvers are made with 16 gauge galvanized steel and are certified for air performance and water penetration by AMCA. The LE line features 6 extruded aluminum, to ensure that they'll stand up to the harshest environments, are built to last, and have the look and functionality that you desire.

The Benefits of AWV’s Fixed Louvers

Our fixed louvers provide architects, contractors, and building owners with many advantages:

AWV architectural louvers produce aesthetically pleasing buildings.

High aerodynamic efficiency lowers air resistance, to reduce the fan energy needed to introduce the ventilated air into or exhausted air out of the building.

AWV louvers come in a wide variety of sizes, shapes, materials, finishes, and coatings to meet the needs of any project.

Efficient AWV louvers provide proven and tested performance against air and water penetration.

AWV Options and Accessories

AWV offers an expansive selection of options and accessories to simplify installation and provide the functionality required for fixed aluminum louvers:

Insect/bird screens and hinged access doors

Hidden or exposed mullions

Variable blade spacing and angles

Mounting angles, glazing tabs, and flanged frames

Sill extensions and blank-off panels of various dimensions

Mounting angles, glazing tabs, and flanged frames

Non-welded and welded construction in varying material thicknesses

Applications for Fixed Aluminum Louvers

Fixed aluminum louvers can be found anywhere there is a need for clean air. The application and aesthetic requirements will drive the look and specifications of the louvers, but the main function stays the same. Fixed louvers can be found in a multitude of different applications:

Parking garage rain protection

Building ventilation intakes and exhaust

Equipment screening

Penthouse equipment ventilation

Why Choose AWV Fixed Aluminum Louvers?

For more than 100 years, American Warming and Ventilating has been advancing technology through product innovation, lowering costs, and bringing better products to market.

When looking for a fixed aluminum louver with an industry-leading reputation, look no further than AWV. To learn more about why AWV’s fixed aluminum louvers are the right fit for your next project, reach out to their experts today.